What is an Internal Combustion Engine?

An internal combustion engine is a type of machine that is designed to convert stored chemical energy into kinetic energy. This is accomplished through the intermittent, although precisely timed, combustion of fuel (i.e. gasoline, diesel) in the presence of an oxidizer (i.e. air) within the confines of a combustion chamber. Most automotive internal combustion engines utilize a two- or four-stroke piston design, but rotary engines have also seen limited use.

Contents

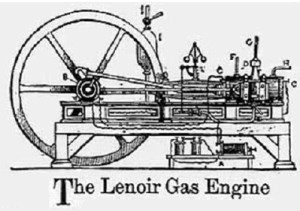

History of the Internal Combustion Engine

Prior to the 19th century, the development of internal combustion engines was held back by the lack of appropriate fuel sources. Some very early predecessors of the modern internal combustion engine used fuels like hydrogen, coal dust, and coal gas. It wasn’t until the rise of petroleum in the 1850s that an appropriate fuel source became widely available, and the development of these engines experienced a rapid expansion from then on.

The first commercially successful internal combustion engine appeared in 1960, and the modern Otto cycle appeared not too long after that. Many other innovations that are recognizable today also appeared during the 19th century, including spark plugs, ignition coils, magnetos, the boxer engine, and the diesel cycle.

Although the nascent automobile industry experimented with a number of types of engines and fuel sources, including very early electric and hybrid cars, the gasoline-powered internal combustion engine dominated throughout the 20th century.

Also see: History of the Internal Combustion Engine

Types of Internal Combustion Engines

Internal combustion engines can be categorized based on the type of fuel, layout, and other factors (i.e. whether they utilize air cooling or water cooling.) Some of the most common types of engines, by fuel type, are:

- Gasoline engines

- Hybrid electric

- Flex fuel

- Diesel engines

- Biofuel (SVO, WVO)

Additionally, the main internal combustion engine configurations are:

- Reciprocating piston

- Two-stroke

- Four-stroke

- Diesel

- Rotary (pistonless)

- Wankel

- Atkinson

Basic Principles of Internal Combustion Engines

At the most basic level, an internal combustion engine converts chemical energy into kinetic energy. This process involves combusting a fuel, in the presence of an oxidizer, within a closed environment. In reciprocating piston engines, the upward motion of the piston compresses the air/fuel mixture, which is ignited either via a spark (gasoline engines) or by the mechanism of compression itself (diesel engines.) The rapidly expanding exhaust gases that are created by the combustion process then drive the piston down, and the process repeats.

The action of the pistons moving up and down causes a component known as a crankshaft to rotate, and every other system on the vehicle harnesses that kinetic energy. The crankshaft is coupled in some way to a transmission, which transmits kinetic energy from the engine to the drive wheels. It is also coupled via belts to various accessories, like an alternator, power steering pump, etc, which are necessary to the proper operation of the vehicle.

Basic Components of an Internal Combustion Engine

Different engines have a variety of component parts, but some of the constituent parts of most piston-driven engines include:

- Cylinders

- Pistons

- Crankshaft

- Connecting rods

- Camshaft

- Spark plugs/glow plugs

Gasoline Internal Combustion Engines

Modern gasoline engines typically use the Otto cycle, although Wankel rotary engines have also been used, and some gas/electric hybrids use an Atkinson cycle engine. In any case, these engines burn gasoline, which is known as petrol in British English, as a fuel source.

While many small gasoline engines are two-stroke, nearly every gasoline engine used in a production automobile today utilizes the four-stroke Otto cycle. This means that these engines have one “power stroke” (where combustion actually forces the piston to rotate the crankshaft) for every four strokes of the piston. In these applications, a “stroke” is defined as the movement of a piston from the top of its throw to the bottom, or vice versa.

Throughout the process of the Otto cycle, each piston goes through four distinct strokes, or steps:

- Intake

- Compression

- Combustion

- Exhaust

During the intake stroke, an air/fuel mixture is drawn into the combustion chamber. This is a “downward” stroke that increases the interior volume of the combustion chamber, which is what draws the air/fuel mixture in (except in the case of direct injection.) Then the piston travels upward again, which compresses the air/fuel mixture. This compressed air/fuel mixture is then combusted, which forces the piston down again in the “power” stroke.

Rotary Gasoline Engines

Rotary engines can also use gasoline as fuel, but they work a little differently. Instead of multiple pistons that move up and down multiple times per cycle, rotary engines have a triangular rotor that creates three combustion chambers within a roughly oval-shaped housing.

Like piston engines, pistonless rotary engines also have four steps:

- Intake

- Compression

- Ignition

- Exhaust

Each side of the triangle-shaped rotor forms a separate combustion chamber within the main oval-shaped housing, and these combustion chambers change shape and volume as the rotor spins. When a chamber passes the intake, it draws in a mixture of air and fuel, which is compressed due to the modified oval shape of the housing. When it is compressed, a spark is used to ignite it, and the expanding exhaust gasses drive the forward progress of the rotor before they are released through the exhaust.

Diesel Internal Combustion Engines

Diesel engines use a modified four-stroke process since the very first one was developed by Rudolph Diesel specifically to improve on the Otto cycle. To that end, they have intake, compression, combustion, and exhaust strokes. However, diesel engines don’t use spark to ignite an air fuel mixture.

In diesel engines, the intake stroke draws in air rather than an air/fuel mixture, and it is this volume of air that is compressed during the compression stroke. This air is so hot due to being compressed that it is able to ignite diesel fuel that is sprayed into the combustion chamber without the need for a spark plug.

Since diesel internal combustion engines don’t use spark plugs to ignite air/fuel mixtures, a number of cold start methods have been used. The most common method makes use of glowplugs that heat up the air either in pre-chambers or directly in the combustion chambers.