What is a Vacuum Hose?

A vacuum hose, which can also be referred to as a “line” or a “tube,” is a flexible rubber connection that routes manifold vacuum to various components and accessories. Since vacuum can be used to power everything from a vacuum brake booster to a windshield wiper motor, a vehicle may contain dozens of these hoses. Vacuum tees, trees, valves, and other connection accessories are used to route vacuum as efficiently as possible.

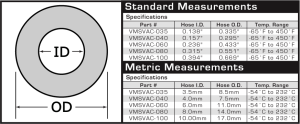

The smallest vacuum lines have a 3/16″ inner diameter (ID), and the biggest ones are typically 5/8″ ID hoses that provide manifold vacuum to a brake booster. Adapters are available to convert from one ID to another, but it’s typically best to use properly sized vacuum hoses whenever replacing them.

Contents

What Vehicles Use Vacuum Hoses?

Virtually every vehicle that runs on gas has at least some vacuum hoses, but they can also be found in some vehicles that run on diesel. Although diesel engines don’t naturally produce vacuum, some diesel engines are equipped with a throttle plate or a vacuum pump to allow them to produce it. This is primarily to enable these vehicles to use the same vacuum accessories that gasoline-powered vehicles use.

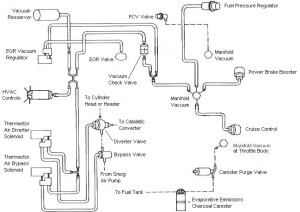

Cars and trucks from the late 1980s and the early 1990s tended to have the most vacuum hoses due to their increasingly complex emissions controls, and vacuum diagrams for vehicles from that era can be incredibly complex. In some cases, properly hooking up a vacuum system for a vehicle from that era can be nearly as complicated as the electrical wiring.

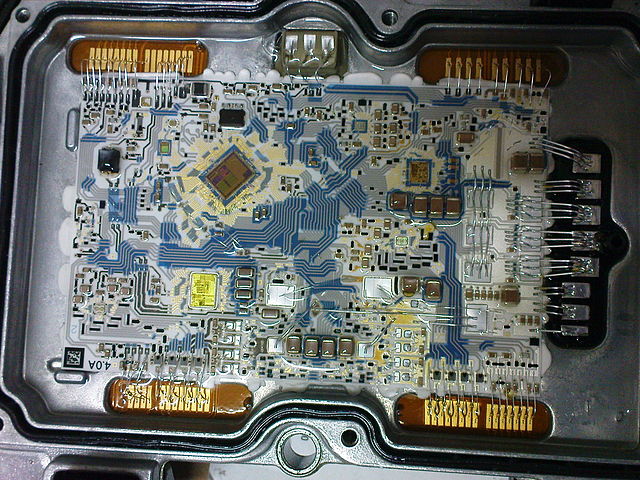

Modern vehicles continue to use vacuum hoses, although they typically don’t use that many. Since modern fuel injection systems are computer controlled, and other things like ignition timing are also computer controlled, vacuum lines are typically only needed for components like brake boosters and PCV valves.

What are Vacuum Hoses For?

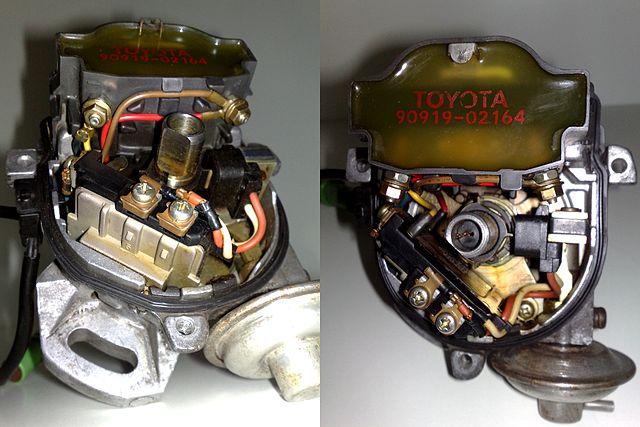

Early on in the history of the automobile, manifold vacuum was harnessed to power a number of different accessories and components. This was mainly due to the fact that early electrical systems were incapable of handling very heavy loads, and manifold vacuum, as a natural byproduct of the normal operation of internal combustion engines that run on gasoline, was readily available.

Since it isn’t feasible to attach most accessories and components directly to an intake manifold, vacuum hoses essentially “transmit” vacuum from the manifold to wherever it is needed. To that end, a manifold will have one or more vacuum ports that act as vacuum sources. Vacuum lines are then used to connect those ports to various components and accessories. In many cases, you will also find vacuum ports on carburetors and throttle bodies.

Some of the most common components that can require vacuum include:

- vacuum advance

- brake booster

- PCV valve

- heater control valve

- HVAC controls

- EGR valve

Types of Vacuum Hoses

The term “vacuum hose” can refer to all of the flexible tubes that transmit vacuum throughout a vehicle, but the terms “vacuum line” and “vacuum tubing” are sometimes used to smaller diameter hoses. Some of the most common inner diameters of vacuum hoses are:

- 1/16″ (2mm)

- 3/32″ (3mm)

- 1/8″ (4mm)

- 5/16″ (8mm)

- 3/8″ (9/10mm)

In addition to the inner diameter size, vacuum lines are also differentiated by the materials that they are made of. Most vacuum hoses are made out of rubber, which is acceptable for most applications. However, silicone vacuum lines are also available for applications where the tube is exposed to a lot of heat.

When Should Vacuum Hoses Be Replaced?

Since most vacuum hoses are made out of rubber, they to break down and wear out over time. That means that they can be replaced as a part of your regular preventive maintenance, but it’s mainly up to personal preference.

Unlike other rubber components, like drive belts, coolant hoses, and brake lines, a vacuum line failure typically won’t post an immediate threat to your safety (i.e. no brakes) or damage your engine (i.e. overheating.) You will experience an extremely stiff brake pedal if your brake booster loses vacuum, but it isn’t very common for a vacuum line like that to suffer a sudden and catastrophic failure.

If one or more vacuum lines do fail, then you may want to consider replacing them all. You may also want to consider replacing a vacuum line if you notice visible signs of cracking or it starts to leak. (You may be able to hear an audible hissing sound when a vacuum hose develops a leak.)

How Do You Replace Vacuum Lines?

Replacing vacuum lines is a relatively simple operation that can typically be performed with few (or no) tools. Vacuum lines are “press fit,” which means that they are held in place by the fact that the inner diameter of each tube is slightly smaller than the outer diameter of the nipple or port it is connected to.

- The general steps for replacing a vacuum line are:

- Remove the hose from both the vacuum source and the accessory

- Make note of where it was connected

- Measure the vacuum hose and the ID (you may want to cut the hose and measure a section that hasn’t been “stretched”)

- Obtain a replacement hose with the proper ID and cut a section of an appropriate length

- Install the new hose to the vacuum source and the accessory

In that process, there are a few snags that you may run into. For instance, vacuum lines often become “stuck” on the ports that they are connected to. In those cases, you may have to cut the hose lengthwise with a box cutter and then peel it off.

If you are replacing a lot of hoses at once, you may want to speed the process up by removing all the hoses, cutting all the replacements at once, and then installing the replacements. If you do approach the job like that, then it’s important to start off by checking the engine compartment for a vacuum diagram. These diagrams will typically be located on the underside of the hood, on a strut tower, or on the radiator core support, and you can use them to verify that you have hooked everything up right when you’re done.