What is a Fuel Injector?

Fuel injectors are the components that are responsible for the final stage of fuel delivery in fuel injection systems. High pressure fuel is delivered to the injector, which is activated by an engine control unit or fuel injector control module. When activated, the injector momentarily opens a valve that allows a precise amount of fuel to spray out.

Although a fuel injection system may have a single injector (i.e. central-point injection) or several (i.e. multiport injection), and injectors vary somewhat in design from one application to another, they all perform that same basic function.

Contents

Types of Fuel Injectors

There are a few different kinds of fuel injectors, and while they all perform the same function (spraying a precise amount of fuel when activated), they don’t all have the same components or design. The three main types of fuel injectors are:

- built into a throttle body (single point injection)

- centrally located (central port injection)

- located at each cylinder (multiport injection, direct injection)

The reality is that the many different types of fuel injectors are much more complex than those three generalized categories, and there are a number of subtypes of each, but we’ll consider these basic types of injectors for the sake of brevity.

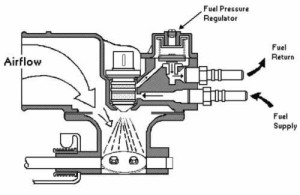

Throttle Body Injectors

In throttle body injection systems, the fuel injector is built right into the throttle body. These throttle bodies represented an easy way for OEMs to switch over from carburetors to fuel injection systems, and the very first single-point fuel injection systems in the 1940s actually referred to their throttle bodies “pressure carburetors.” Today, the term “carburetor” refers exclusively to fuel mixing devices that rely on the Venturi effect rather than a pressurized spray of fuel.

The simplest single-point fuel injection systems consist of a single injector that slots into the throttle body. This injector is similar to other fuel injectors, but it is responsible for delivering fuel to the entire engine rather than just one cylinder. When it is activated, it sprays a fine mist of fuel into the throat of the throttle body, where it mixes with air and passes into the intake manifold. Since that results in the air/fuel mixture traveling all the way from the throttle body to the intake ports, this type of fuel injection is sometimes referred to as a “wet manifold system.”

Throttle body injectors can sometimes be replaced by simply unbolting the injector and installing a new one, although some can only be serviced by removing and rebuilding the entire throttle body. Some throttle bodies also have multiple built-in fuel injectors in a manner that recalls the design of multi-barrel carburetors.

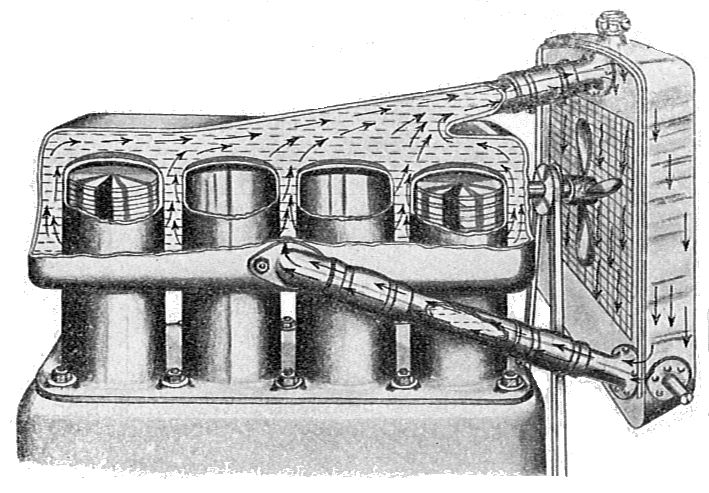

Central Port Injectors

In central port fuel injection (CPFI) systems, a single “maxi” injector is used to provide fuel to all of the cylinders. However, this central injector is connected to each intake port via nylon fuel lines, which makes CPFI a sort of hybrid between single-point and multiport fuel injection.

In most central port injection systems, the fuel injector is an integral part of an assembly that includes components like:

- a fuel pressure regular

- nylon fuel lines

- poppet valve nozzles

This is sometimes referred to as the “spider assembly,” and it has to be replaced as a unit. That means if any one component fails (whether it’s the central “maxi” injector fails, a valve starts to leak, or the regulator breaks down), the whole thing has to be replaced.

Multiport and Direct Fuel Injectors

Most gasoline and diesel engines today use multiport or direct fuel injection, which both use similar fuel injectors. These injectors are stand-alone units, each of which is responsible for providing fuel to a single cylinder. The main difference is that multiport injectors deliver the fuel to the intake right at each intake port, and direct injectors spray the fuel straight into each combustion chamber.

Multiport Fuel Injector Components

A typical multiport fuel injector consists of a:

- structural body/housing

- inlet

- filter basket

- electrical connector

- solenoid

- pintle valve

- pintle valve return spring

- pintle cap

- pintle seat

- outlet

The body or housing of a fuel injector contains all of the component parts, which are typically serviceable. On the top end of the housing, an 0-ring allows the body to be sealed to a fuel rail, and another o-ring on the bottom side allows it to be sealed into an intake runner or cylinder head. At the fuel rail side, just inside the main fuel injector body, a filter basket helps keep contaminants from passing through the injector and obstructing the pintle valve.

The electrical connector provides a method for an ECU or fuel injector control module to activate the solenoid, which is an electromagnetic coil that operates the pintle valve. When the solenoid activates, the pintle valve pulls back from its seat and a small amount of fuel is sprayed through the pintle nozzle.

How Does a Fuel Injector Work?

Although they all perform the same function, fuel injectors don’t all work in precisely the same way. The two main types of fuel injectors use either a:

- poppet valve

- pintle valve

Fuel Injector Pintle Valves

Fuel injectors that use pintle valves are operated by electromagnetic components called solenoids. The solenoid is activated, or “pulsed” by an ECU or fuel injector control module, which causes it to undergo linear movement (which is how solenoids operate.)

Since the solenoid is mechanically connected to a pintle valve within the fuel injector, that linear movement causes the pintle to move away from its seat. A small amount of highly pressurized fuel then sprays from the pintle nozzle.

Fuel Injector Poppet Valves

In fuel injection systems that use poppet valves, fuel pressure is used to operate the valve rather than the direct action of a solenoid. The central “maxi” injector receives a constant amount of pressurized fuel, which it directs to each cylinder via nylon tubes that terminate in poppet valves.

When sufficient pressure reaches one of these poppets, it is forced open, which results in a fine mist of fuel spraying into an intake port. When the pressure is relieved, the poppet valve closes again.

Fuel Injector Pulse Width

Fuel injectors are “open” for periods of time that can be measured in millionths of a second. This minuscule time period is referred to as the “fuel injector pulse width.” Since the pulse width indicates how long a fuel injector is open, it corresponds directly to how much fuel is actually delivered to each cylinder.

Fuel Injector Failure

Fuel injectors can fail due to simple mechanical issues, but the most common points of failure are the result of issues like leaks and contamination. Fuel injector leaks typically occur when one of the o-rings fail, although leaks in CPFI systems are often the result of a bad injector tube or poppet valve. In the former case, replacing the o-rings will fix the problem, while the latter typically calls for the replacement of the entire spider assembly.

When a fuel injector fails (or begins to operate poorly) due to contamination, it typically has to be replaced or cleaned. Although a number of “fuel injector cleaner” products are available, many “dirty” injectors actually have contaminants inside their filter baskets that can only be removed by taking the injector apart. Dirty injectors can also have contaminants inside their pintle valves or seats that prevent them from closing entirely, which can often be treated with an ultrasonic cleaner and various chemical solvents.

After fuel injectors have been cleaned or rebuilt, it’s also important to flow test and flow balance them before returning them to service.