What is an Ignition Module?

An ignition module is the component in electronic ignition systems that functions as the contact breaker for the coil or coils. In most basic terms, an ignition module is an electronic replacement for old, mechanical contact breakers like ignition points. These components are also referred to as “ignition control units” and “ignitors,” and their main purpose is to interrupt the flow of current through the primary winding of an ignition coil and create a high voltage pulse in the secondary winding. Since these modules are an example of solid state electronics, they aren’t subject to the same sort of wear and tear that points suffer from, so they tend to have relatively long service lives.

Contents

Ignition Module History

The first electronic ignition systems were experimented with in the late 1940s, but internal combustion engines continued to use point breaker ignition systems for several more decades. The first aftermarket electronic ignition system was offered in 1962, but these early systems were essentially designed to take some of the load off the points by using the points to activate a transistorized switching unit (the prototypical ignition module), which was then responsible for activating and deactivating the primary coil winding.

Throughout the early history of electronic ignition systems, ignition modules were used in two types of systems: breakerless, solid state ignition systems and in systems that still used mechanical points. For instance, Pontiac offered an optional breakerless system on some models in 1963, but other manufacturers (like Chrysler, for some 1967 Dodges and Plymouths) continued to use “ignition amplifiers” in conjunction with mechanical points.

Chysler’s first breakerless electronic ignition system debuted in 1971, and all of their vehicles were using it by 1973. This system was very similar to modern electronic ignitions in that it utilized a magnetic hall effect sensor instead of mechanical points and included a transistorized switching device (the ignition module.)

How does an Ignition Module Work?

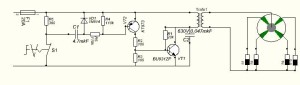

Ignition modules are solid state switching devices that typically use a component like a transistor to switch the current flow through the primary winding of an ignition coil on and off. In that way, an ignition module works a lot like mechanical points. However, ignition modules are not able to do the job alone. Whereas points were mechanically operated by the rotation of the distributor shaft, an ignition module requires some type of external input in order to activate.

Hall Effect Sensors

Most vehicles use a component known as a “hall effect sensor” to activate the ignition module. In essence, a hall effect sensor is a device that produces a small current in response to a changing magnetic field. That makes it sort of like an electronic counterpart to ignition points.

Where ignition points physically open and close in response to the movement of an eccentric ring on the shaft of a distributor, a hall effect sensor produces a small current in response to the movement of a reluctor on the shaft of a distributor. As the reluctor rotates, it causes the hall effect sensor’s magnetic field to expand and contract, which in turn generates a small current that is precisely timed to the rotation of the engine.

Breakerless Contact Breaking

Ignition modules vary in appearance from one application to another, but they all perform the same basic function.

In ignition systems that use a hall effect sensor and an ignition module, the electrical current from the hall effect sensor is what activates the ignition module. When the ignitor receives an input from the hall effect sensor, it uses a solid state component like a transistor to open and close a circuit that connects the primary winding of the ignition coil to the battery. This causes a magnetic field around the winding to expand and collapse, which produces high voltage pulses in the secondary winding. These pulses are then delivered to the spark plugs either via a distributor cap, rotor, and spark plug wires, or directly (in the case of distributorless ignition systems.)

Ignition Module Failure

When an ignition module fails, the engine will not start or run. This is due to the fact that the ignition module is responsible for activating the ignition coil, which itself is responsible for firing the spark plugs. In some cases, an inoperable ignition module can be traced to wiring or fuse problems, which is why it’s important to make sure that the connections between the module and the battery, the module and the coil, and the module and the hall effect sensor are all good. If the ignition module isn’t receiving battery voltage, after all, it can’t complete (or break) the circuit to the coil.

Ignition modules can also fail internally due to heat and other stresses that build up over time. In some cases, an ignition module that fails like that will start to act up when it gets hot, which can cause sputtering or dying issues once a vehicle gets up to operating temperature. When a vehicle fails to start after a heat soak, or dies when the engine is hot, and then starts up just fine when cold, a bad ignition module may be suspected. However, it’s important to test the module while the dying or no-start condition is present, as it may test good when cold.

Testing and Replacing an Ignition Module

Although replacing an ignition module is a relatively simple operating, testing these components can be a little more complicated. In general, you’ll need to check to make sure that it’s receiving battery voltage and that it is transmitting a signal to the coil when you crank the engine, but the exact test procedures can vary from one ignitor to another. There are professional tools that are specifically designed to test ignition modules, but there are typically also diagnostic procedures that you can follow with a more basic set of tools (like a multimeter and test light.)

Some ignition modules can be located by simply looking at the distributor, as demonstrated by this aftermarket GM unit.

Ignition modules are typically located on, inside, or near the distributor, but that isn’t always the case. If you don’t know where your ignition module is located, then you’ll have to check a wiring diagram or manual to fin out before you can replace it. In some cases, you can also just take a look at your ignition system to find out where it is located. Some modules that are located inside distributor caps are actually visible by looking at the base of the cap, and in other cases you can simply trace the wiring harness that comes out of the cap, or the harness connected to the coil, to find the ignition module.

After you have located your ignition module and determined that it needs to be replaced, you will need to disconnect the battery. You can then disconnect the wires (or wiring harness) from the module and then unbolt it. In some cases, you will have to remove the distributor cap first.

Replacing an ignition module is a simple bolt-on type repair, but you may need to clean the mating surface and apply some dielectric grease. When this is necessary, you will typically find a tube of the appropriate material in the box that your replacement ignition module comes in. After that, you can simply bolt the new unit in place, plug it in, and reconnect the battery.

excellent and helpful guide-bravo !