What is a Mass Air Flow Sensor?

A mass air flow sensor (also known as a MAF) is component that is used to meter the amount of air that enters the intake system of an internal combustion engine. Since modern gasoline engines have to maintain tight control over the air/fuel ratio, it is imperative that there be a way to determine how much air is entering the system at any given time, and mass air flow sensors are one way to accomplish this.

There are a number of different technologies that these devices can employ, including spring-loaded door flaps, vortex sensors, membrane sensors, and both hot and cold wire sensors.

Contents

The Importance of Air Mass

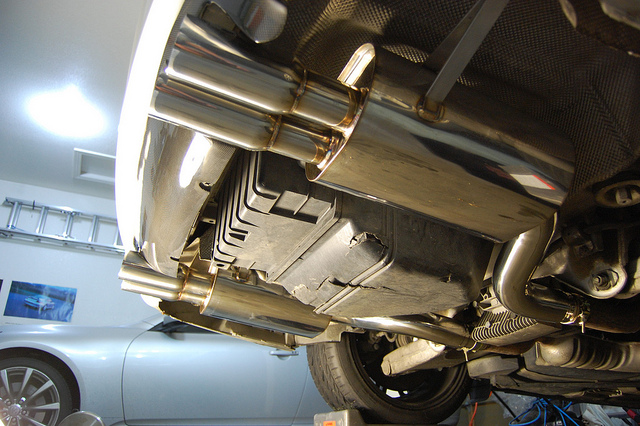

Modern internal combustion engines are, in simplest terms, big air pumps. Air enters through the intake, feeds the combustion process, and is expelled through the exhaust. The constant pumping of the pistons, and the powerful vacuum that this action creates, serves to suck in enough air through the intake to enable combustion, and the explosive force of combustion serves to force the air and various byproducts out through the exhaust. This is all rather simple in theory, but modern internal combustion engines are also finely-tuned machines that require precise mixture ratios of air and fuel to operate properly.

Since air is a gas, the mass of a single volume of air can vary widely depending on factors like pressure and temperature. As atmospheric pressure drops, any given volume of air will have less mass than it did at a higher pressure, and the same is true for high temperatures versus low temperatures. That’s why simply measuring the volume of air that passes through the intake won’t work. In order for an engine control unit (ECU) to “know” how to set the air/fuel mixture, it has to know exactly how much air is entering the system at any given time.

Types of Mass Air Flow Sensors

There are a lot of different ways to measure the mass of any given volume of air, both directly and indirectly, but the vast majority of MAFs use one of two different methods: vane meter and hot wire. These are both indirect methods that require additional sensor inputs, which means that if those sensors fail, the ECU isn’t able to properly calculate the mass of the air entering the intake.

Vane meter sensors, which are also known as volume air flow (VAF) sensors, are mechanical in nature. They consist of a housing that contains a flap or door that is spring-loaded. The housing is mounted in-between the air filter and the intake manifold, so any air that enters the intake has to pass through it. As the intake draws air in, the flap is forced open. The volume of the air can then be determined by measuring the angle of the flap. To that end, this type of sensor includes a potentiometer that is attached to the flap.

Of course, simply knowing the volume of the air that enters the intake system isn’t enough. To that end, this type of MAF often includes a built-in intake air temperature (IAT) sensor. Between the volume of the air and the temperature of the air, the ECU is then able to calculate its mass with some degree of accuracy.

The other main type of mass air flow sensor is known as a “hot wire sensor.” This type of MAF is also installed in-line between the air filter and the intake manifold, but it doesn’t use a flap. Instead, there is a thin wire suspended inside the housing. This wire is “hot” in that it has a current passing through it. Since the resistance of the wire increases and decreases depending on its temperature, that resistance can be used to calculate roughly how much air is passing through the MAF at any given time.

Unlike vane sensors, hot wire MAFs are able to measure mass without an additional temperature sensor. This is due to the fact that dense air will tend to cool the wire down more than air that is less dense, which allows the resistance reading of the wire to indicate the mass of the air rather than simple its volume.

Other types of mass air flow sensors, including cold wire and vortex sensors, are used less frequently. Cold wire sensors measure the inductance of a sensor that changes depending on how much air is flowing over it, and vortex sensors operate by creating an oscillating series of Karman vortices within the sensor housing. There are a couple of different ways that these vortices can be measured, but in any case it is the frequency of the oscillations that allows the air mass to be determined.

When a Mass Air Flow Sensor Fails

Since modern engines depend on mass air flow sensors to correctly set the air/fuel mixture, a failed mass air flow sensor can cause a whole slew of driveability issues. You may experience a significant drop in fuel economy, a lack of power, or the engine may not even run well enough to drive the vehicle. There are some cases where a fouled MAF can be repaired and returned to service, but in most cases these (typically expensive) components simply have to be replaced.